Jun 28,2020

Photovoltaic power generation system experimental instrument, solar photovoltaic power generation training station

The indoor photovoltaic power system training platform is composed of solar cell module, battery module, controller module, off-grid inverter module, load regulation control module, monitoring instrument module, PC monitoring module, and other one-sided components.

1. Experimental instruments for photovoltaic power system

The indoor photovoltaic power system training platform is composed of solar cell module, battery module, controller module, off-grid inverter module, load regulation control module, monitoring instrument module, PC monitoring module, and other one-sided components.

2. Teaching and Research Training Project

Demonstration and test of light energy change course of low power solar cell

Test 1, photovoltaic touch block unit composition principle.

Test 2, solar photovoltaic cell energy conversion combination principle.

Test 3, in the difference between the sky and the sunshine intensity of the light wave on the photovoltaic conversion to obey the influence of the test.

Test 4, the effect of solar orbit change in different seasons on photovoltaic energy conversion test.

Test 5, in different seasonal environmental temperature changes on the impact of photovoltaic energy conversion test.

Test 6, solar cell direct load test.

Demonstration and test of system control operation process

Test 1, solar controller under voltage protection test.

Test 2, solar controller charging overvoltage protection test.

Test 3, solar controller charging temperature compensation test.

Test 4. Simulated solar street light system test (6WLED light panel with light distributor)

Test 5. Three output mode test of the controller, manual switch switching or jumper (manual on/off, light control on/off, light control on/off)

Test 6. Inverter inverter principle test (through the test of each test point of the inverter)

Test 7. Inverter and mains complementary test (manual switching)

Test 8: Inverter output overload protection test

Test 9: Inverter output undervoltage and overvoltage protection test

Test 10: Charging test of solar battery replaced by commercial power (switched by manual toggle switch)

Test 11. Inverter principle test of grid-connected inverter (through the test of each test point of inverter)

Test 12. Output overload protection test of grid-connected inverter

Test 13: Output undervoltage and overvoltage protection test of grid-connected inverter

Test 14. Relative test on effective connection and separation control of grid-connected inverter MPPT and electronic tracker.

Test 15, grid-connected inverter into the grid power supply interfix, the inverter should stop supplying power to the grid within 2s, the anti-islanding effect protection test.

3. Technical conditions for operation of training system (single-phase output)

Power generation unit

Light energy

The photovoltaic module power: 20Wp

◆ PV module output part-time voltage: 17.5VDC

◆ Part-time current of photovoltaic module: 1.14A

Electric energy storage unit

◆ Battery type: maintenance-free gel battery

◆ Battery capacity: 12V/7Ah

◆ Number of batteries: 1

Control unit

◆ Solar charge and discharge controller: part-time voltage 12V current 10A; Three output modes: manual on and off, light control on and off, light control on and off.

◆ Off-grid inverter power supply: output waveform sine wave, frequency 50HZ ± 1HZ; Rated input voltage 0.8V ~ 17V, current 12A; Rated output voltage 220VAC 10%, rated output power 150W; Output power factor ≥ 95% (linear load) inverter compliance: ≥ 82%.

◆ Synchronous inverter power supply: DC input voltage 12VDC, grid-connected output voltage 180 ~ 260VAC, grid-connected frequency range 47.8~51.2Hz, output power 200W, frequency 50Hz, compliance 98.5, power factor> 0.99, large MPPT:12 ~ 17.5VDC. It can be directly connected to the grid through photovoltaic cells and storage batteries.

◆ Input mains: part-time voltage AC220V, frequency 50HZ;

◆ Part-time environment: 0 ℃ ~ 40 ℃, ≤ 85% RH

Performance unit

3, 4, 1, digital performance

◆ DC voltmeter: photocell charging voltage/battery actual voltage, switching each other;

◆ DC ammeter: photocell charging current/inverter input current, switching each other;

◆ Exchange voltmeter: inverter output voltage;

◆ Exchange ammeter: inverter output current;

◆ Temperature/humidity meter: show the current temperature, humidity and time of the laboratory.

3, 4, 2, LED performance

◆ Solar controller: charging, overvoltage, undervoltage, overdischarge, operation;

◆ Battery voltage (high-medium-low);

3, 4, 3, digital tube performance

◆ General opening and closing;

◆ Light control on and light control off;

◆ Light control on and off;

Switch unit

_Photovoltaic cell control switch;

◆ Inverter control switch;

◆ Resistive load control switch;

_Photovoltaic cell control switch;

Load unit

◆ Exchange linear resistance load: 3~15~120W

◆ DC analog load: 12V/6W

Monitoring software (optional)

◆ PC monitoring module: monitoring host, monitoring software, performance screen.

◆ Performance content: battery voltage, photovoltaic voltage, photovoltaic current, photovoltaic power, energy simulation diagram.

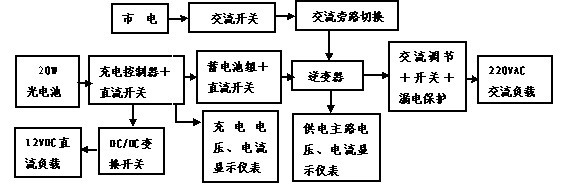

4, photovoltaic power system training platform part-time principle block diagram